Q &A with National Association of Tower Erectors (NATE) Executive Director Todd Schlekeway

The TV Answers Blog talked with Todd Schlekeway about the challenges of TV station frequency moves (often referred to as the spectrum repack) from a tower crews’ perspective. Learn more about why these transitions are happening and how you can plan to rescan at TVAnswers.org.

Q: From the perspective of a tower crew, what is the process of changing a station’s frequency?

A: The process of physically changing a station’s frequency varies because TV tower sites are unique to their respective locations and geographical terrain. The procedures implemented depend on if the TV antenna is a top mount, top double-stacked antenna, mounted on a candelabra or side mounted on the tower. The most difficult jobs are the double-stacked top mount antennas and those located on a candelabra tower. Furthermore, an escalated degree of difficulty exists based on a tower’s location and the surrounding area.

Q: Can you briefly explain a standard case of this process?

A: The process of manufacturing the antennas involved in the repack is time-consuming in and of itself and can take many weeks just to build an antenna. In most cases, the customer and/or broadcast contractor must have an engineer of record perform a structural analysis of the tower. From there, modifications must be completed to accommodate the new antenna loading requirements on the tower. Once completed, an interim antenna may be required for the station to remain on air while the work continues.

Next, the crew will often be required to remove the transmission line to the antenna from the tower. Once a determination is made to re-purpose or replace the transmission line and their work is complete, the tower crew is ready to install the new antenna. Changing out the antenna is normally the last part of the project for the crew to conduct in order to transition to the station’s post-repack frequency.

Q: How long does this process typically take?

A: The length of a project depends on a number of different factors but some of the complex sites can take as long as six months or more for one dedicated tall tower crew. Some tower crews work a minimum of 8-9 hours per day (Monday – Friday) and another 5-6 hours on Saturday. Crews are often out on the road 3-4 weeks at a time and weather challenges/shipping delays can extend these projects even further.

Q: Is there an effort underway to import tower crews from abroad to supplement the high demand the repack has put on American crews?

A: Some companies are supplementing their tower technician workforce by bringing in crews from select European countries. However, NATE’s workforce development initiatives to date have been primarily focused on developing a long-term, sustainable domestic labor pool. Many companies have opted not to bring in crews from other countries due to the difficult and lengthy process of obtaining work visas and all of the legal paperwork that comes with that.

Q: How many tower crews are operating in the United States right now?

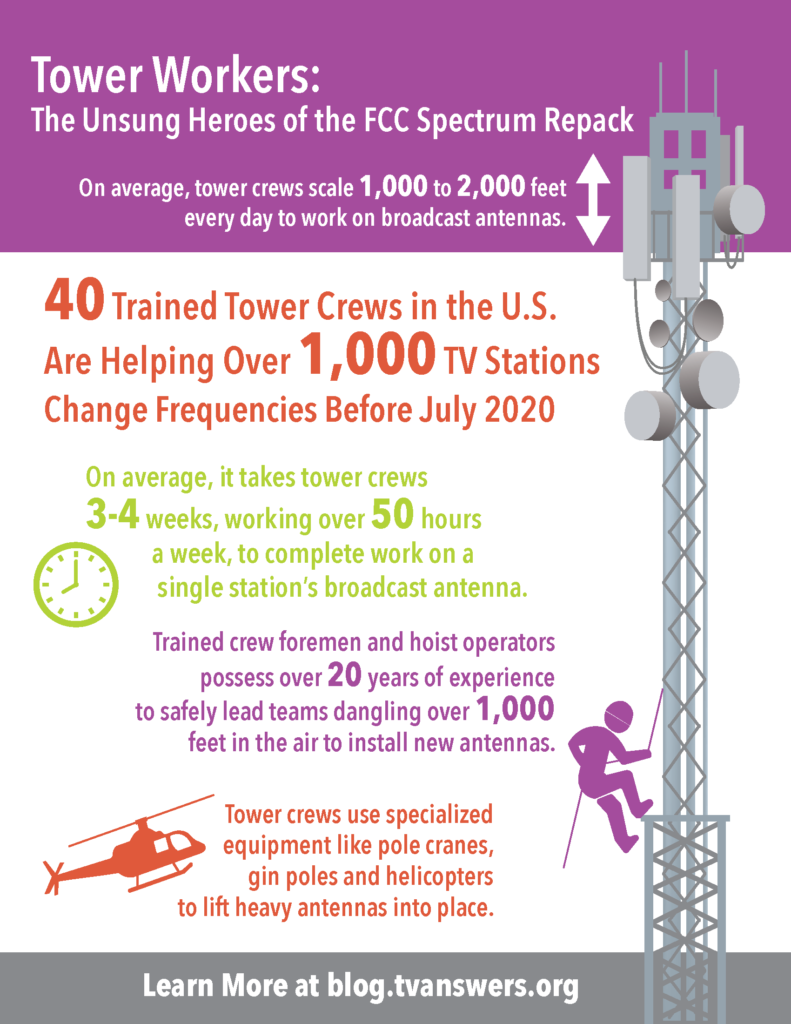

A: NATE estimates that there are approximately 40 crews (typically consisting of 5-6 tower technicians per crew) in the country that are truly capable of performing work on these broadcast towers. Of these 40 crews, less than 30 are capable of performing complex large broadcast tower work.

Additionally, these broadcast crews have foremen and hoist operators who possess over 20 years of experience. So, we are talking about a very skilled, specialized group of tower technicians who are truly capable of performing the complexities involved with repack antenna projects.

Q: Despite thorough safety measures, there have been recent tragic deaths of tower workers. Have those tragedies affected your procedures or safety protocols?

A: NATE’s focus and commitment from the very beginning of this process has been to ensure that broadcast repack transition work is conducted in the safest manner possible to ensure that the technicians return home safely every night.

That being said, there are always valuable lessons to be learned from industry fatalities. It is crucial that all personnel possess necessary training and onsite supervision when working on these towers. Companies involved in the repack must invest in a strong safety and training program and enforce a culture centered around safety embedded from the top-down to be implemented by every tower crew.

The uncontrollable factors associated with broadcast-related tower work and tight labor market is currently driving the supply/demand workforce issues the industry is experiencing. However, NATE is committed to investing heavily in workforce development initiatives that we believe can help alleviate some of the labor challenges over time.

Q: With the inherit risk involved when climbing broadcast towers, what safety measures do your crews take to get safely back to the ground?

A: The average working height of crews on broadcast towers can range from 1,000 to 2,000 feet, so a concentrated focus on safety training is paramount in this industry. It’s extremely important that all repack-related work be conducted in adherence to all training guidelines, safety protocols, OSHA (Occupational Safety and Health Administration) requirements and national consensus standards.

The OSHA compliance directive has enhanced safety at tower sites by providing procedures for tower crew personnel when using a hoist to take employees to or from workstations on communication towers. This Compliance Directive (CPL) applies to all work activities on communication towers that involve the use of a personnel hoist and is significant as it reduces the amount of climbing associated with tower work, thus reducing risk.

Comprehensive rigging plans must also be developed and followed when planning work on tall tower sites. After a tower is properly rigged, tower technicians can often access their work location on the tower by safely “riding the hoist line,” using a personnel man basket and/or by accessing a functional elevator system on the tower.

Q: What advice do you have for stations that are just starting their repack work?

A: It is important for stations to be proactive in the repack process by preparing in advance. Stations need to secure a qualified broadcast contractor company with experienced tall tower crews and schedule a time to perform all of the structural analysis and tower-site work that goes into the repack transition phase.

Obtaining a qualified tower crew at this point in the repack timeline will likely pose a challenge, given the fact that most qualified crews are booked through the final phase. However, stations must not compromise safety or quality by hiring inexperienced tower crews. If qualified crews are not readily available to be hired, stations should consider having a standby or interim antenna at the ready to switch over to in order to meet their phase deadline. This will allow more time for a qualified crew to complete the tower modifications, as well as antenna and line work.